Specialty Polymers Market: Exploring Niche Applications and Market Opportunities

The Specialty Polymers Market is estimated for 2023 for the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

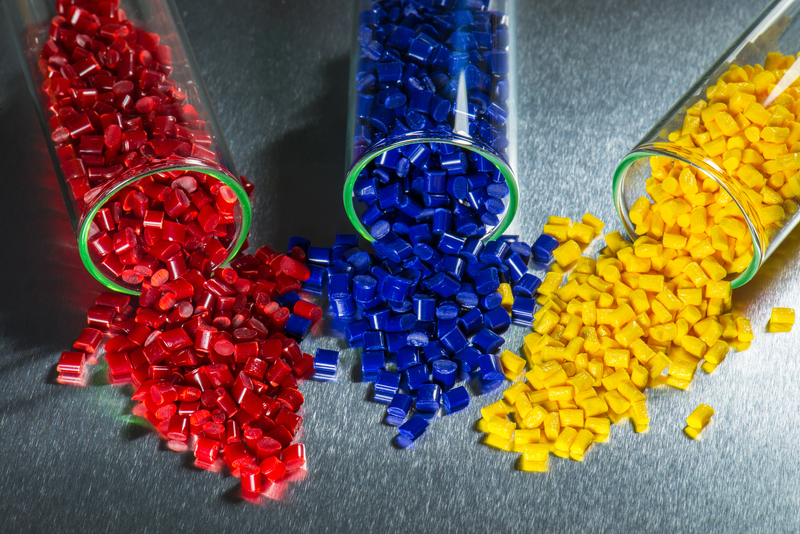

Specialty polymers are engineered polymers that exhibit superior mechanical properties, thermal stability, and resistance to chemicals. They find widespread applications in industries such as automotive & transportation, consumer goods, electrical & electronics, and construction.

Market Dynamics:

Specialty polymers are gaining high traction owing to their ability to enhance performance and impart unique properties not found in commodity polymers. They are increasingly replacing metals in applications that require high strength, low weight and corrosion resistance. Additionally, the growing demand from end-use industries such as automotive and construction is expected to fuel the market growth over the forecast period. Developments in the field of nanotechnology have led to the introduction of nano-fillers and nano-composites that are enabling multi-functional material designs and driving innovation in the specialty polymers market.

Major Drivers of Demand for Specialty Polymers:

Increased Demand from Automotive Industry Driving Growth

Specialty polymers are extensively used in the automotive industry for applications such as seals, hoses, gaskets, dashboards, bumpers, speakers, instrument panels, protective coatings, and more. The growing automotive industry especially in emerging economies will continue to drive increased demand for specialty polymers.Globally the automotive industry is growing at a healthy pace driven by factors such as rising disposable incomes, increasing automobile ownership in developing nations, increasing preference for technologically advanced features in vehicles and the trend of shared mobility services. As vehicles incorporate more plastics which are replacing conventional materials like metals to reduce weight and increase fuel efficiency, demand for lightweight yet durable specialty polymers from automotive manufacturers will rise in the coming years.

Rise in Electronics and Electrical Sectors Boosting Consumption of Specialty Polymers

The electronics and electrical sectors have undergone rapid transformation in the past decade due to growing digitization and connectivity trends. New technologies like IoT, 5G networks, artificial intelligence are driving innovation in electronics. At the same time, miniaturization of devices and components is increasing. Specialty polymers play a crucial role in this industry thanks to their unique properties like heat resistance, electrical insulation, compatibility with integrated circuits and ability to withstand various manufacturing processes involved in electronics. Rising electronics consumption worldwide especially driven by demand for smartphones, laptops, smart wearables and other smart home devices is propelling specialty polymer uptake in this end use segment.

Major Restrain for Specialty Polymers Market: Volatility in Raw Material Prices Hindering Market Growth

Specialty polymers are derived from petroleum based raw materials like propylene, ethylene and benzene which are hydrocarbon monomers. Prices of crude oil and natural gas from which these raw materials are obtained undergo fluctuations depending on geopolitical issues, production cuts, demand-supply dynamics and economic cycles. Any increases in raw material costs lead to a corresponding rise in specialty polymer prices. This price volatility acts as a major restraining factor for consistent demand and market growth. For specialty polymer producers, unstable raw material costs make operations and planning difficult. It also discourages investments in capacity expansions. On the customer side, uncertain polymer costs impact their procurement budgets and ability to take on new projects involving specialty polymer applications. Overall price volatility in hydrocarbon feedstock poses significant challenges for the specialty polymers industry.

Major Opportunity for Specialty Polymers Market: Growing Demand from Healthcare Sector Presenting Opportunities

The healthcare industry has emerged as a significant end user of specialty polymers. They find wide applications in medical devices, pharmaceutical packaging, medical equipment and apparatus, implants and prosthetics, tissue engineering and more. Medical device manufacturers are increasingly using specialty polymers for their biocompatibility, flexibility in manufacturing and ability to impart desired mechanical properties. Strict regulatory approvals for materials used in healthcare applications is driving preference for specialty polymers over conventional alternatives. Rising health awareness, aging populations and increasing income levels worldwide are leading to higher healthcare spending and consumption of medical goods. This presents substantial opportunities for specialty polymer producers to cater to the growing needs of the healthcare sector with innovative materials.

Major Trend in Specialty Polymers Market: Increasing Adoption of Sustainable and Bio-Based Specialty Polymers

With growing environmental consciousness, regulations on carbon emissions and disposal of plastics waste, there is a definite trend of shifting towards more sustainable specialty polymer options. Producers are investing in R&D to develop bio-based and biodegradable specialty polymers from renewable feedstock like plants, agricultural waste etc. rather than petroleum. Biopolymers offer the performance properties required for specific applications while being earth-friendly. Their uptake is increasing in applications such as packaging, textiles, 3D printing materials and consumer goods. As sustainability gains prominence among OEMs, brand owners and consumers, bio-specialty polymers will dominate future market growth trends. Their production will also open up new revenue opportunities from waste conversion and environmental services.

Comments

Post a Comment