Intelligent Pigging Growth Accelerated by Increasing Pipeline Integrity Monitoring Needs

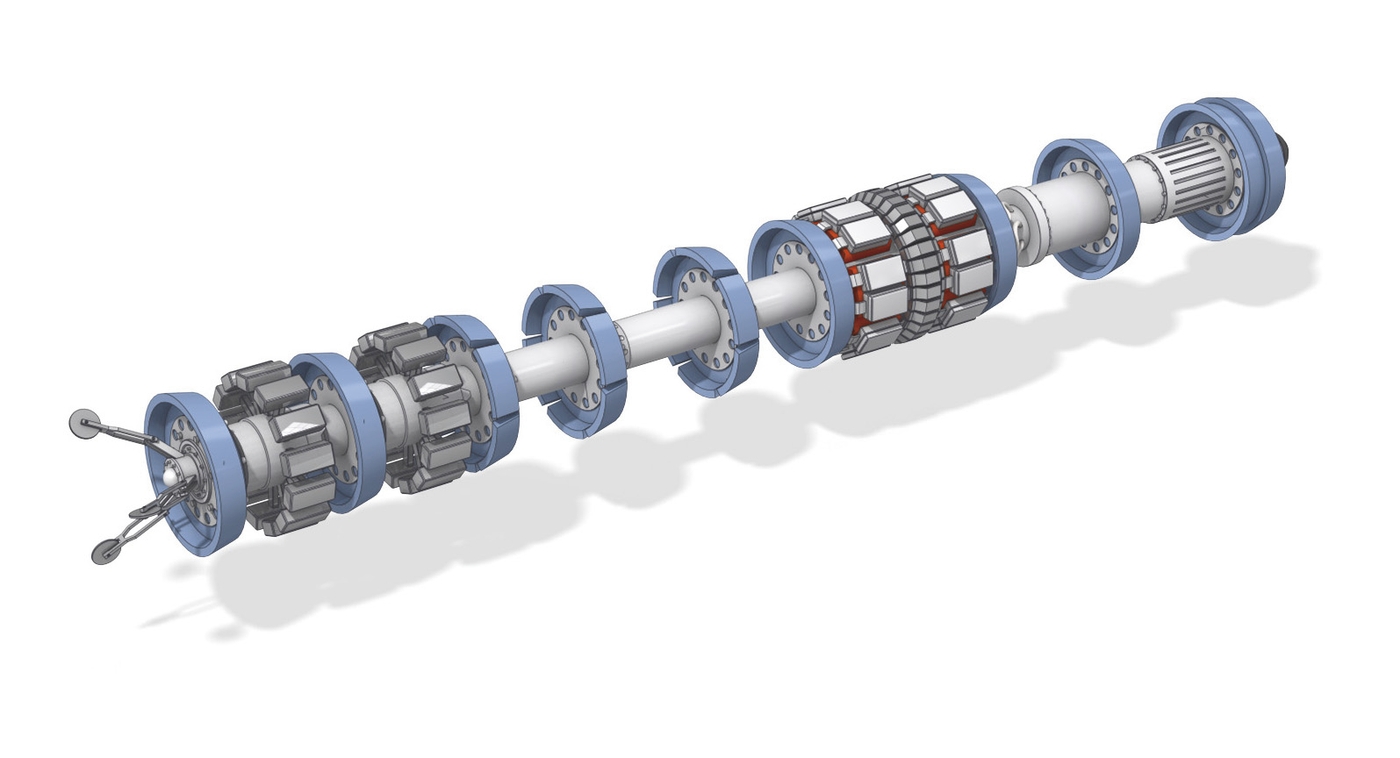

Intelligent pigging technology involves the use of in-line inspection tools known as smart pigs or intelligent pigs to inspect and monitor oil and gas pipelines for defects, corrosion and other anomalies without disrupting the flow. Intelligent pigs help detect any potential defects and leaks in pipelines to ensure pipeline integrity and safety. With growing concerns around aging oil and gas infrastructure and pipelines worldwide, the demand for continuous pipeline monitoring solutions like intelligent pigging is surging to prevent accidents and unplanned downtime.

The global Intelligent Pigging Market is estimated to be valued at US$ 1,408.3 Bn in 2023 and is expected to exhibit a CAGR of 6.5% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market key trends:

The increasing need for pipeline integrity monitoring and assessment is a key trend driving growth of the intelligent pigging market. Pipelines transport a major portion of oil and gas globally and integrity issues pose serious safety, environmental and economic risks. Intelligent pigs deployed through pipelines help detect defects early and reduce the likelihood of failures and accidents. They can inspect up to 100% of the pipeline length providing critical data to pipeline operators. This is helping boost adoption of intelligent pigs as a preventive maintenance approach and ensure continued safe operation of aging pipeline infrastructure worldwide. Advanced technologies like ultrasonic testing, geometry tools and magnetic flux leakage are also enhancing capabilities of intelligent pigs.

Segment Analysis

The global intelligent pigging market is dominated by magnetic flux leakage technology segment. Magnetic flux leakage technology helps detect corrosion and cracks, and allows to capture the amount and location of metal loss over large distances. It is most cost-effective for pipelines which experience internal and external corrosion. With growing need to ensure pipeline integrity and prevent spillage, magnetic flux leakage technology segment is expected to continue dominating the intelligent pigging market during the forecast period.

Key Takeaways

The global intelligent pigging market is expected to witness high growth over the forecast period. Advancements in inspection technologies coupled with stringent government regulations regarding pipeline safety and integrity are the key factors driving the growth. The global Intelligent Pigging Market is estimated to be valued at US$ 1,408.3 Bn in 2023 and is expected to exhibit a CAGR of 6.5% over the forecast period 2023 to 2030.

Regional analysis

North America region currently dominates the global intelligent pigging market. Presence of extensive pipeline network for transportation of oil & gas and strict government regulations regarding pipeline safety in the US and Canada are propelling the growth of intelligent pigging solutions in the region. Asia Pacific region is expected to witness the fastest growth during the forecast period due to rising pipeline infrastructure and increasing focus on operational safety.

Key players

Key players operating in the intelligent pigging market are LIN SCAN, T.D. Williamson, Inc., Baker Hughes Incorporated, GE Oil and Gas, NDT Global, Enduro Pipeline Services, Inc. LIN SCAN is one of the leading players providing intelligent pigging solutions globally. The company offers variety of inspection tools and services for pipeline inspection. GE Oil and Gas provides both internal and external intelligent pigs for detecting cracks, corrosion and geometry issues to ensure pipeline integrity.

Comments

Post a Comment