Emerging Trends in the Stone Plastic Composite Flooring Market: A Comprehensive Overview

The Stone Plastic Composite Flooring Market is estimated for 2023 for the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

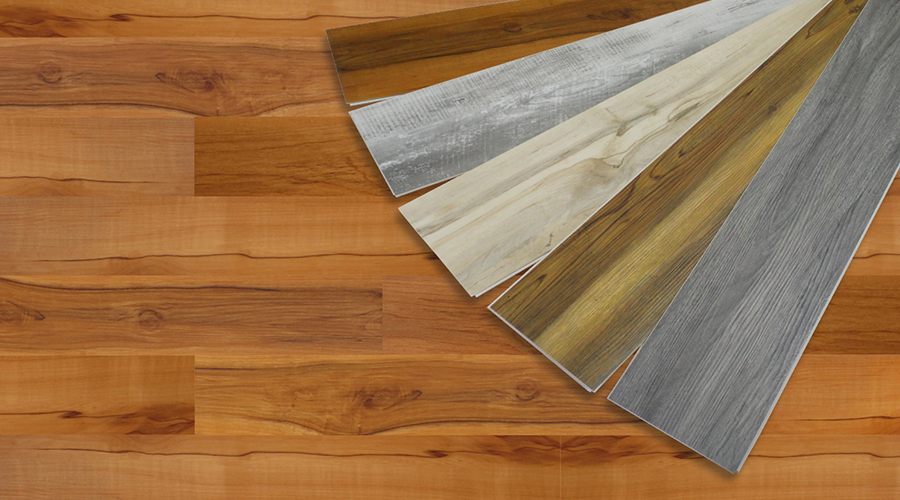

Stone plastic composite flooring, also known as SPC flooring, is a type of floating waterproof flooring that resembles natural stone or hardwood. It provides robust durability for both residential and commercial spaces such as homes, offices, retail stores etc.

Market Dynamics:

Growing renovation and construction activities across both developed and developing regions are driving the growth of the global stone plastic composite flooring market. According to U.S. Census Bureau, the total construction spending in 2022 is estimated to reach USD 1.91 trillion, witnessing a 7.8% growth over 2021 spending levels. Further, steady expansion of real estate sector in countries like China, India, Mexico etc. has increased the demand for quality flooring solutions like stone plastic composite flooring which offers attractive looks and enhanced durability when compared with traditional materials like ceramic tiles. Additionally, rising consumer preference for environment-friendly and sustainable flooring alternatives is also fueling the market growth over the forecast period.

Increasing awareness about advantages of stone plastic composite flooring driving the market growth

Stone plastic composite (SPC) flooring offers various advantages over traditional flooring options like wood, tiles and laminates. It is highly durable, water resistant, scratch resistant and does not get damaged by termites or fungus. SPC flooring resembles natural stone but is much more affordable. It can withstand heavy foot traffic and looks as good as new even after years of use. These properties make SPC flooring ideal for both residential and commercial spaces.

Rising environmental consciousness increasing demand for eco-friendly flooring alternatives

There is a growing desire among consumers to reduce their environmental footprint. Traditional flooring materials like wood, natural stone and even laminates involve damaging natural resources during extraction and manufacturing. SPC flooring on the other hand is made from recycled materials like plastic and stone dust without causing significant harm to the environment. It can also be recycled at the end of its lifecycle. Many builders and architects are recommending SPC flooring for green building projects due to its sustainable attributes. This is driving more consumers to opt for eco-friendly stone plastic composite flooring solutions.

Increasing penetration of organized retail raising consumer awareness

Earlier, consumers had limited exposure to different flooring options. However, the growth of organized retail in interior infrastructure and building materials has significantly improved product visibility and education. Retailers showcase various flooring samples and educate buyers about material properties, maintenance requirements, longevity, warranty coverage etc. This enables well-informed choice making. SPC flooring manufacturers are partnering with retailers to promote their environment-friendly, durable and affordable products. Growing consumer awareness through organized distribution channels is helping stone plastic composite flooring gain wider acceptance.

Evolving lifestyle trends increasing preference for low maintenance flooring

With dual income families and faster pace of life, convenience has become an important decision factor. Flooring which requires very little care and upkeep fits well into modern lifestyles. SPC flooring does not need regular waxing or polishing like wood and is waterproof eliminating mopping needs. It does not get scratched or dented easily maintaining an elegant look even with rough use and traffic of kids/pets. This low maintenance property appeals to consumers seeking easy to handle flooring options amid their busy schedules. Evolving lifestyle trends will further boost demand for durable yet hassle-free stone plastic composite flooring.

Emergence of new technologies driving product customizationa and innovation

Continuous R&D is enhancing stone plastic composite flooring technology. New embossing techniques are enabling realistic reproduction of different stone textures for a natural look. Hybrid core construction is imparting improved waterproofing, sound insulation and stability. Double UV coating is making surfaces more scratch resistant. New digital printing methods allow custom designs and motifs. Manufacturers are incorporating antibacterial and anti-allergic properties as well for allergy-sensitive users. Ongoing technological developments are expanding design and performance possibilities. This is attracting wider consumer base toward personalized yet high utility stone plastic composite flooring choices.

Comments

Post a Comment