VCI Paper is Fastest Growing Segment Fueling Growth of Volatile Corrosion Inhibitors (VCI) Packaging Material Market

The global Volatile Corrosion Inhibitors (VCI) Packaging Material Market is estimated to be valued at US$ 826 Mn in 2023 and is expected to exhibit a CAGR of 6.2% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Market Overview:

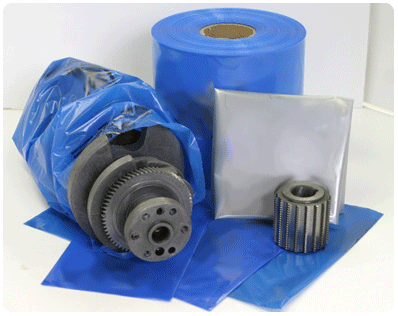

VCI packaging materials contain volatile corrosion inhibitors that protect metal components from corrosion through vapor phase action. They are widely used for packaging ferrous and non-ferrous metals during storage and transportation. The key advantages are corrosion protection and cost savings over time.

Market Key Trends:

Market Key Trends:

One of the key trends in the Volatile corrosion inhibitors packaging material market is the rising usage of VCI paper. VCI paper provides corrosion protection to ferrous metals for up to two years. It contains volatile corrosion inhibitors that are released into the headspace of the package to form a protective mono-molecular layer. Compared to other VCI packaging formats such as films and foils, VCI paper offers better breathability that allows optimum protection. As a recyclable and environmental-friendly option, VCI kraft paper has gained significant traction in the recent years.

Segment Analysis:

The global volatile corrosion inhibitors (VCI) packaging material market is segmented on the basis of type, end-use industry, and region. Based on type, the market has been divided into vapor inhibitors, non-vapor inhibitors, and liquid coatings. The vapor inhibitors sub-segment is expected to dominate the market over the forecast period owing to its various advantages such as effectiveness on ferrous and non-ferrous metals and dual protection from corrosion and moisture.

Key Takeaways:

Key Takeaways:

The global volatile corrosion inhibitors (VCI) packaging material market size is expected to reach US$ 1,376 Mn by 2030, expanding at a CAGR of 6.2% over the forecast period. The increasing demand for corrosion-protected packaging from various end-use industries such as electronics, automotive, aerospace & defense is expected to drive the market growth.

Regional Analysis:

Regional Analysis:

Regionally, North America dominates the global volatile corrosion inhibitors (VCI) packaging material market and is expected to continue its dominance over the forecast period. The region accounts for a market share of over 35% due to stringent regulations regarding corrosion-protected packaging and presence of key players. Asia Pacific exhibits the fastest growth over the forecast period owing to growth of end-use industries in developing economies such as India and China.

Key Players:

Key Players:

Key players operating in the volatile corrosion inhibitors (VCI) packaging material market include Cortec Corporation, Branopac GmbH, Armor Protective Packaging, Protective Packaging Corporation, Nefab Group, Daubert Industries, Inc., Zerust Excor, and Metpro Group. Cortec Corporation currently dominates the market due to its wide product portfolio and global presence across 40 countries.

Comments

Post a Comment