Polyphenylene Ether Compounds Market: Emerging Trends and Future Prospects

Polyphenylene Ether Compounds Market: An Overview

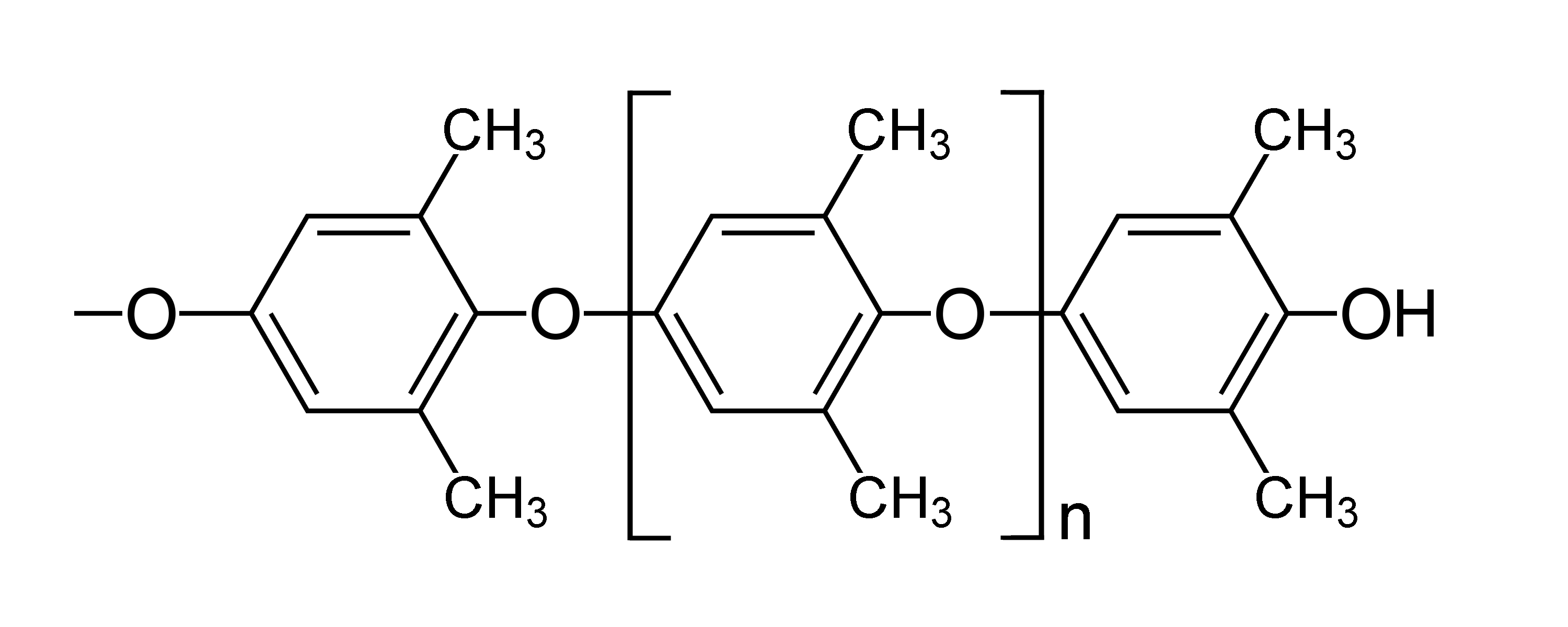

The Polyphenylene Ether Compounds market is a dynamic and evolving segment of the chemical industry. These compounds, often referred to as PPE, are high-performance thermoplastics known for their exceptional thermal and electrical insulating properties. They find widespread use in various applications across industries, making them a critical part of the global market.

Definition: Polyphenylene Ether Compounds, or PPE compounds, are a class of thermoplastic polymers known for their high-temperature resistance, dimensional stability, and excellent electrical insulating properties. They are primarily derived from polyphenylene ether resin and various additives, resulting in a versatile material suitable for a range of applications.

Market Overview & Scope: The Polyphenylene Ether Compounds market has witnessed steady growth in recent years due to their unique combination of properties. These compounds are extensively used in the automotive, electrical and electronics, and industrial sectors. In the automotive industry, PPE compounds are employed in various parts, such as connectors, switches, and motor components, due to their ability to withstand high temperatures and resist electrical arcing. Moreover, the growing demand for lightweight materials in the automotive sector has boosted the adoption of PPE compounds.

In the electrical and electronics industry, PPE compounds find use in the manufacturing of connectors, insulators, and circuit boards. The increasing demand for smaller and more efficient electronic devices further fuels the demand for these compounds. In the industrial sector, PPE compounds are used for applications where heat resistance and electrical insulation are crucial, making them suitable for components like pumps, valves, and filters.

Market Growth: The Polyphenylene Ether Compounds market is expected to witness significant growth in the coming years. This growth is attributed to the expanding application areas, increasing technological advancements, and the growing demand for high-performance materials in various industries. As the world continues to focus on energy efficiency and sustainability, PPE compounds are likely to play a vital role, given their recyclability and potential for reducing environmental impact.

Market Industry: The market for Polyphenylene Ether Compounds is highly competitive, with several key players involved in the manufacturing and distribution of these materials. Companies in this industry are constantly innovating to develop new formulations of PPE compounds to meet the evolving needs of end-users across different sectors. Additionally, strategic partnerships and collaborations are common within the industry to expand market reach and diversify product portfolios.

Trends: The polyphenylene ether compounds market trends is witnessing rise in current market scenario. One of the key trends is the increasing use of these compounds in 3D printing and additive manufacturing. This trend is driven by the desire to create complex, customized parts with high-performance characteristics. Furthermore, the development of PPE compounds with enhanced flame-retardant properties is gaining traction, especially in industries where fire safety is paramount.

In conclusion, the Polyphenylene Ether Compounds market continues to grow and diversify due to its remarkable properties and adaptability to various applications. As technology and industrial needs evolve, this market is expected to play a crucial role in shaping the future of high-performance materials and their applications across industries.

Comments

Post a Comment