Drill Bits For Oil And Gas Market: Innovations Driving Efficiency in Drilling Operations

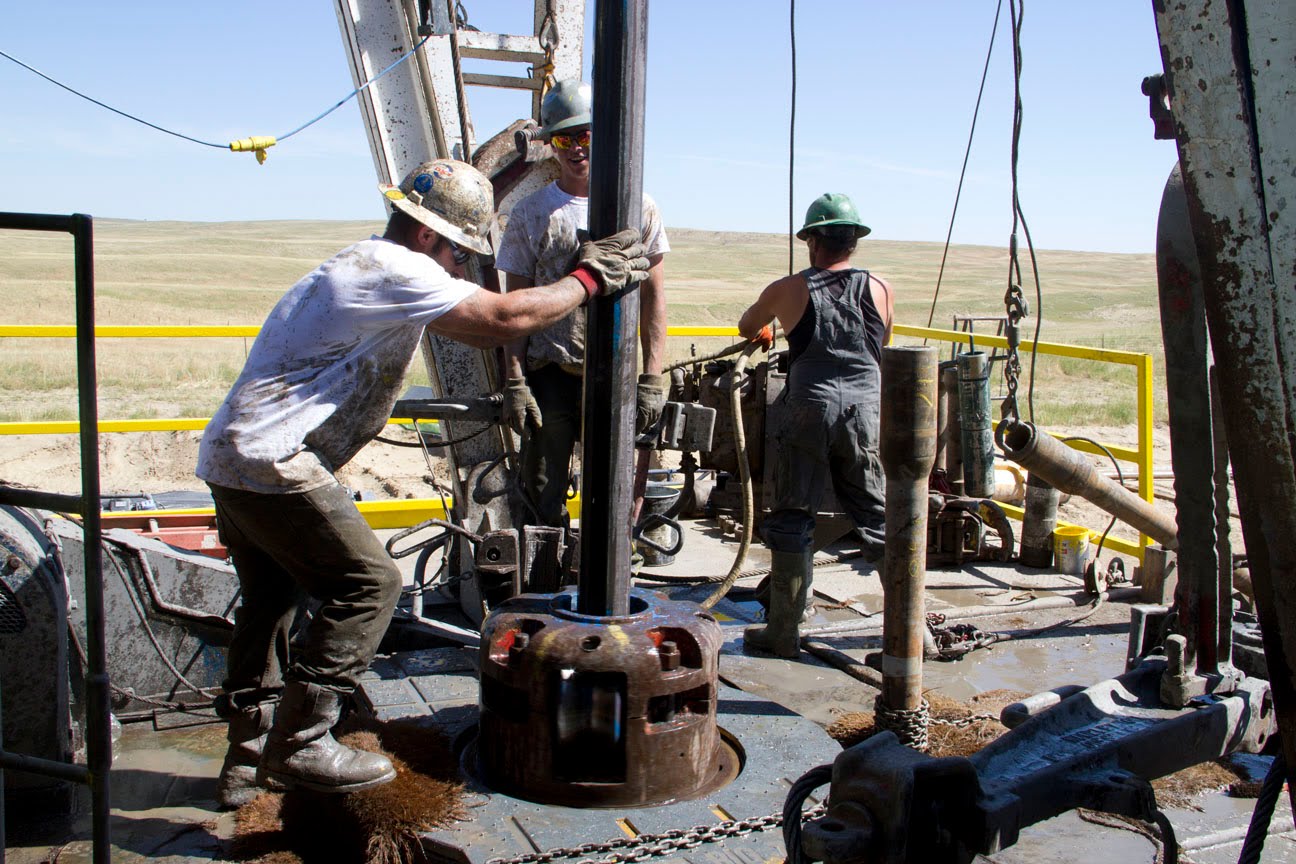

Drill bits for the oil and gas industry play a crucial role in the exploration and extraction of fossil fuels. These specialized tools are designed to penetrate the earth's surface and create boreholes for the drilling of oil and gas reservoirs. The market for drill bits in the oil and gas sector encompasses various types, sizes, and designs of drill bits, tailored to meet the specific needs of drilling operations. This market is a vital component of the global energy industry, directly impacting the exploration and production activities.

The drill bits for oil and gas market provide the essential tools needed to access underground hydrocarbon reserves. It encompasses a wide range of drill bit types, including roller cone bits, fixed cutter bits, and diamond-impregnated bits, each suited to different geological conditions and drilling requirements. These drill bits are utilized in both onshore and offshore drilling operations, serving as a fundamental element in the quest for energy resources.

The market for drill bits in the oil and gas market industry has experienced substantial growth over the years, primarily driven by the increasing global demand for energy. As the world's population continues to grow, so does the need for fossil fuels, making efficient drilling operations essential. Technological advancements in drilling techniques and materials have also contributed to the market's growth, enabling operators to access deeper and more challenging reservoirs.

The oil and gas industry relies heavily on the drill bits market, as they are instrumental in the successful exploration and extraction of hydrocarbons. The market's growth is intertwined with the overall health of the oil and gas sector, subject to fluctuations in oil prices, exploration activities, and geopolitical factors. As the industry seeks to extract hydrocarbons from more challenging environments, such as deepwater reserves and unconventional shale formations, the demand for advanced and specialized drill bits is expected to increase.

Several trends are shaping the drill bits for oil and gas market. Environmental concerns and regulatory pressures are driving the development of eco-friendly drilling technologies, pushing companies to adopt more sustainable practices. Additionally, the adoption of digital technologies, such as data analytics and automation, is enhancing drilling efficiency and reducing downtime, further impacting the market.

In conclusion, the drill bits for oil and gas market is a critical component of the global energy industry, supporting the exploration and extraction of hydrocarbons. It encompasses various types of drill bits designed to meet specific drilling needs and operates in a dynamic environment influenced by technological advancements, environmental concerns, and market conditions. As the world's energy demands continue to rise, the drill bits market is expected to evolve and innovate to meet the industry's evolving requirements.

Comments

Post a Comment