UV Tapes Market: Illuminating the Future of Adhesive Solutions in High-Tech Industries

UV tapes, short for Ultraviolet (UV) tapes, are specialized adhesive tapes that are designed to cure or bond when exposed to ultraviolet light. These tapes find diverse applications across various industries due to their unique properties and capabilities. In this comprehensive overview, we will delve into the definition, market overview, growth factors, industry applications, and emerging trends within the UV tapes market.

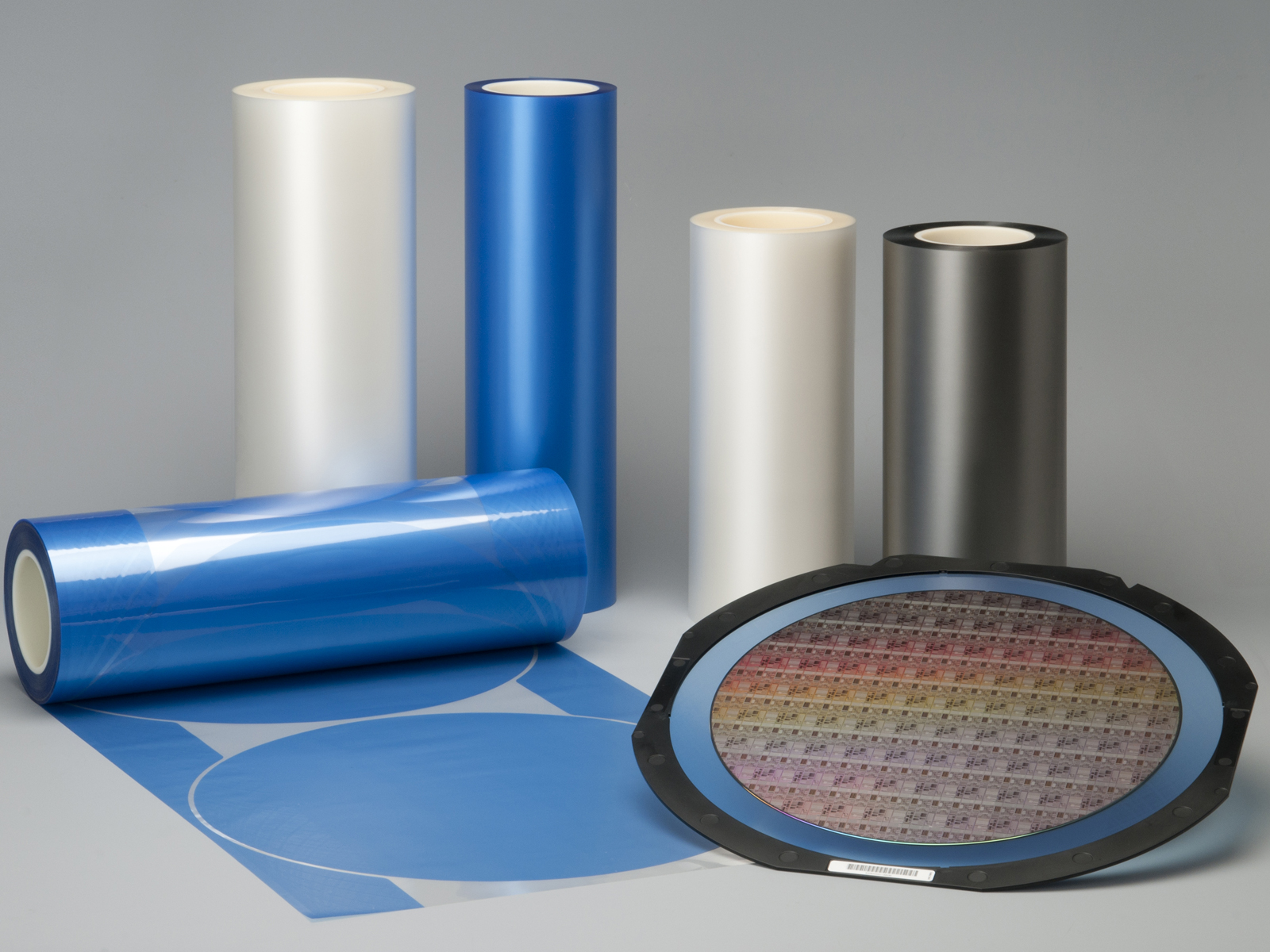

Definition: UV tapes are adhesive materials that exhibit photochemical reactions when subjected to UV light. These tapes are formulated with UV-sensitive compounds that allow them to bond or cure rapidly when exposed to UV radiation. This property makes UV tapes an ideal choice for applications requiring quick and precise bonding, such as electronics assembly, automotive manufacturing, and medical device production.

Market Overview: The UV tapes market has witnessed significant growth in recent years, driven by the increasing demand for advanced bonding solutions in various industries. UV tapes offer several advantages, including fast curing times, high bond strength, and the ability to bond dissimilar materials, which have contributed to their popularity in the market. Key players in the UV tapes market are continuously innovating to expand their product portfolios and cater to the evolving needs of industries.

Market Growth: The UV tapes market growth can be attributed to several factors. Firstly, the electronics industry relies heavily on UV tapes for applications such as semiconductor packaging, LCD assembly, and circuit board bonding. As consumer electronics continue to evolve, the demand for smaller, more efficient, and reliable electronic components has surged, driving the adoption of UV tapes.

Additionally, the automotive sector has embraced UV tapes for various applications, including interior trim bonding and glass installation. The automotive industry's pursuit of lightweight materials and improved safety standards has further fueled the demand for UV tapes.

Industry Applications: UV tapes have found applications in a wide range of industries, including electronics, automotive, medical, aerospace, and packaging. In the electronics industry, they are used for bonding delicate components, while the medical field relies on UV tapes for securing medical devices and instruments. The aerospace sector benefits from UV tapes for their lightweight properties and resistance to harsh environmental conditions.

Trends: The UV tapes market is constantly evolving, and several trends are shaping its future. One notable trend is the development of UV tapes with enhanced sustainability, as industries are increasingly focused on reducing their environmental footprint. Manufacturers are also working on UV tapes with improved thermal and chemical resistance to expand their utility in demanding applications.

In conclusion, UV tapes represent a versatile and essential component in various industries, offering rapid bonding and curing capabilities. As industries continue to advance and demand more efficient and reliable bonding solutions, the UV tapes market is expected to witness sustained growth and innovation in the coming years.

Comments

Post a Comment