Sustainable Biopolymer Revolution: Unraveling the Green Potential of Thermoplastic Starch as a Viable Alternative to Conventional Plastics

In recent years, the world has awakened to the pressing need for sustainable solutions to combat the environmental challenges posed by conventional plastics. One remarkable answer to this problem lies in the realm of biopolymers, specifically thermoplastic starch. As a viable alternative to traditional plastics, thermoplastic starch is rapidly gaining momentum in the sustainable materials landscape due to its renewability, biodegradability, and versatility.

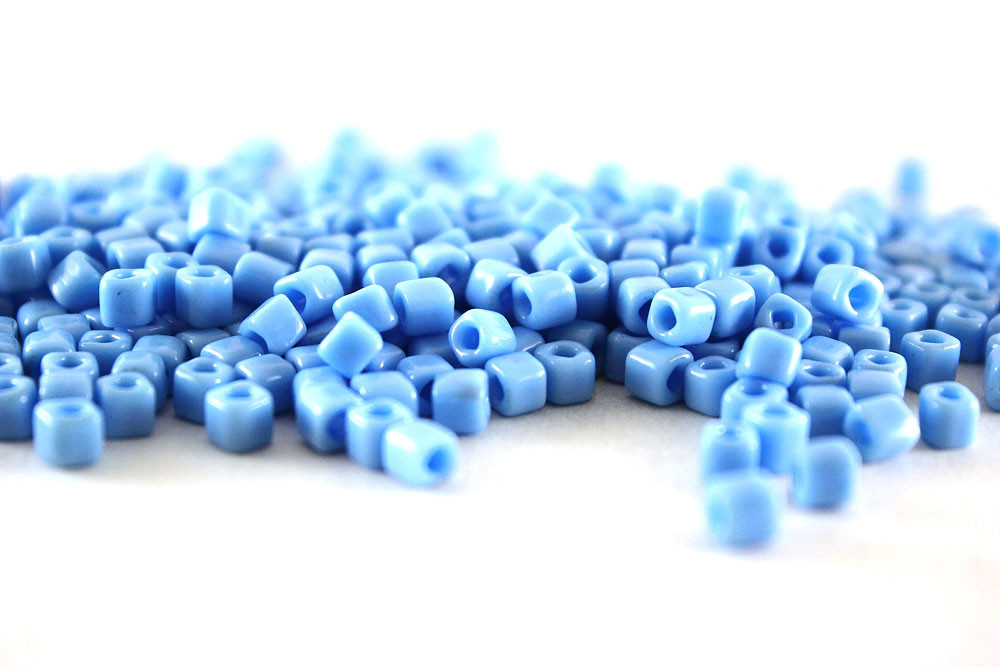

Thermoplastic starch market is derived from a readily available and abundant resource: starch obtained from various agricultural crops like corn, potatoes, and cassava. The production process involves blending the starch with plasticizers and additives to enhance its mechanical properties. The resulting biopolymer boasts outstanding features, including biodegradability, compostability, and non-toxicity, making it an ideal choice for single-use applications, packaging materials, and more.

One of the most significant advantages of thermoplastic starch is its eco-friendliness. Unlike petroleum-based plastics, which persist in the environment for hundreds of years, thermoplastic starch degrades naturally, releasing no harmful toxins in the process. When disposed of properly, it can decompose into carbon dioxide and water with the aid of microorganisms, significantly reducing the burden on landfills and oceans. Moreover, the production of this biopolymer consumes far less energy and generates fewer greenhouse gas emissions compared to conventional plastics, contributing to a more sustainable manufacturing process.

Furthermore, thermoplastic starch exhibits exceptional versatility, allowing for a wide range of applications across industries. Its moldability, transparency, and flexibility make it suitable for manufacturing various products, including disposable cutlery, food packaging, shopping bags, and agricultural films. With the increasing demand for sustainable alternatives, thermoplastic starch offers a viable solution that meets both consumer expectations and environmental requirements.

In conclusion, the rise of thermoplastic starch marks a significant stride towards a sustainable biopolymer revolution. Its green potential as a substitute for conventional plastics is unparalleled, offering a feasible solution to mitigate the adverse environmental impact of single-use plastics. As industries and consumers alike recognize the importance of sustainable materials, the adoption of thermoplastic starch can lead us towards a greener and more environmentally responsible future. Embracing this biopolymer alternative is not just a choice; it is a necessity in our journey towards a more sustainable and harmonious coexistence with the planet.

Comments

Post a Comment