Nickel Alloys Market Analysis, Trends, and Forecasts: Exploring the Future of High-Performance Nickel Alloys

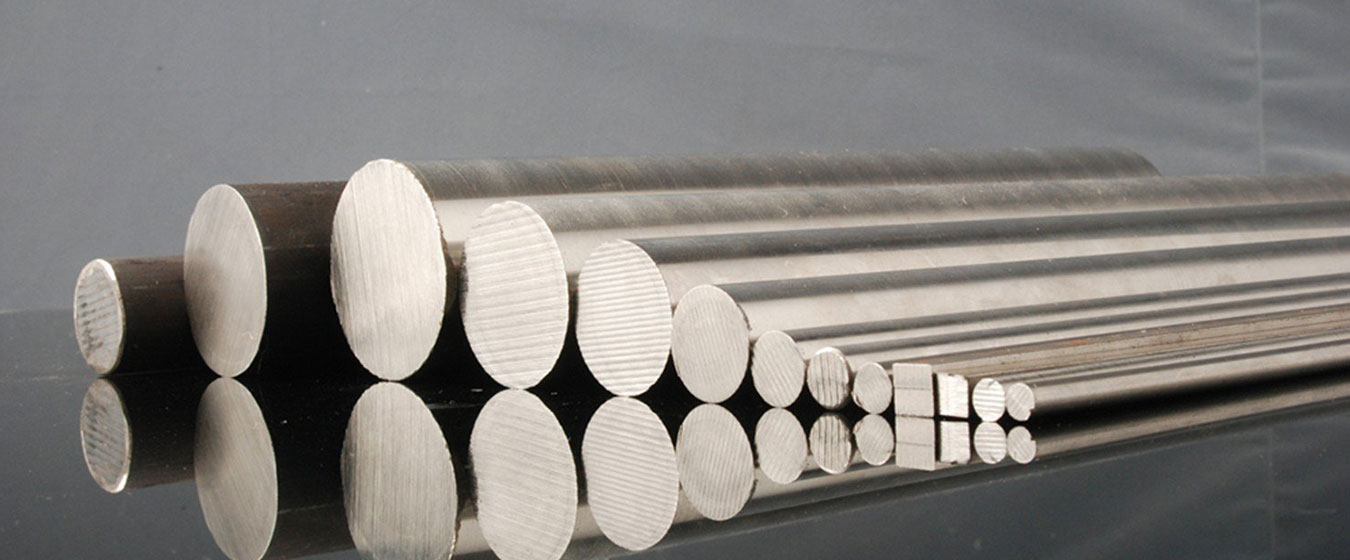

Nickel alloys are metallic materials composed primarily of nickel along with other elements, such as chromium, molybdenum, iron, copper, and others. These alloys are specifically formulated to possess desirable mechanical, physical, and chemical properties, including high strength, corrosion resistance, heat resistance, and electrical conductivity. Nickel alloys are widely used in various industries, such as aerospace, oil and gas, chemical processing, power generation, and medical, due to their unique combination of properties.

The nickel alloys market is a sector of the global metals industry that focuses on the production, distribution, and use of alloys containing a significant amount of nickel. Nickel alloys are metallic materials composed primarily of nickel along with other elements, such as chromium, molybdenum, iron, copper, and others. These alloys possess excellent mechanical, physical, and chemical properties, making them highly desirable for various applications across different industries.

Here is some key information about the nickel alloys market:

Properties and Characteristics:

- High strength: Nickel alloys exhibit exceptional strength and toughness, even at elevated temperatures.

- Corrosion resistance: These alloys are highly resistant to corrosion, making them suitable for applications in harsh environments.

- Heat resistance: Nickel alloys can maintain their mechanical properties at high temperatures, making them ideal for applications in aerospace, power generation, and chemical industries.

- Electrical conductivity: Certain nickel alloys possess excellent electrical conductivity, making them suitable for electrical and electronic applications.

Types of Nickel Alloys:

- Monel: Contains primarily nickel and copper, known for its resistance to corrosion by seawater and other aggressive media.

- Inconel: Contains nickel, chromium, and iron, known for their high-temperature strength and excellent oxidation resistance.

- Hastelloy: Contains nickel, molybdenum, and chromium, offering superior corrosion resistance in various aggressive environments.

- Nimonic: Contains nickel, chromium, and cobalt, known for their high-temperature strength and corrosion resistance.

- Duplex and super duplex stainless steels: These alloys contain a combination of nickel, chromium, and other elements, offering a balanced combination of strength and corrosion resistance.

Applications:

- Aerospace and aviation: Nickel alloys are used in aircraft engines, gas turbines, and other components that require high-temperature and corrosion-resistant materials.

- Oil and gas industry: These alloys are used in oil and gas exploration, drilling, and production equipment due to their resistance to corrosive environments.

- Chemical processing: Nickel alloys find applications in chemical reactors, valves, and pipes, where resistance to corrosive chemicals is crucial.

- Power generation: Nickel alloys are used in power plants for components like gas turbines, boilers, and heat exchangers, where they can withstand high temperatures and pressures.

- Medical and healthcare: Certain nickel alloys are used in medical implants and instruments due to their biocompatibility and resistance to bodily fluids.

Market Outlook:

- Growing demand: The nickel alloys market has been witnessing steady growth due to increasing industrialization, infrastructure development, and technological advancements across various sectors.

- Emerging economies: Countries like China, India, and Brazil are witnessing rapid industrial growth, driving the demand for nickel alloys in sectors such as aerospace, automotive, and energy.

- Recycling and sustainability: With an emphasis on sustainable practices, there is a growing focus on recycling nickel alloys and reducing environmental impact during production processes.

- Research and development: Ongoing research and development efforts are focused on developing advanced nickel alloys with improved properties, expanding their application range.

Major Players:

- Precision Castparts Corp. (PCC)

- Haynes International Inc.

- Allegheny Technologies Incorporated (ATI)

- VDM Metals GmbH

- Carpenter Technology Corporation

- Aperam

- Sandvik AB

- Thyssenkrupp AG

- Rolled Alloys Inc.

- Ulbrich Stainless Steels & Special Metals Inc.

It's worth noting that the nickel alloys market is dynamic, influenced by factors such as raw material prices, economic conditions, and technological advancements. For the most up-to-date and detailed information, it is recommended to refer to industry reports, market research, and news

Comments

Post a Comment