Smart Materials Market: Unlocking Revolutionary Innovations and Market Potential

The smart materials market refers to the industry that focuses on the development, production, and application of materials with advanced properties and functionalities. These materials are designed to respond to external stimuli such as temperature, light, pressure, or magnetic fields, exhibiting unique characteristics and adapting their behavior accordingly. The market for smart materials has witnessed significant growth due to their wide range of applications across various industries.

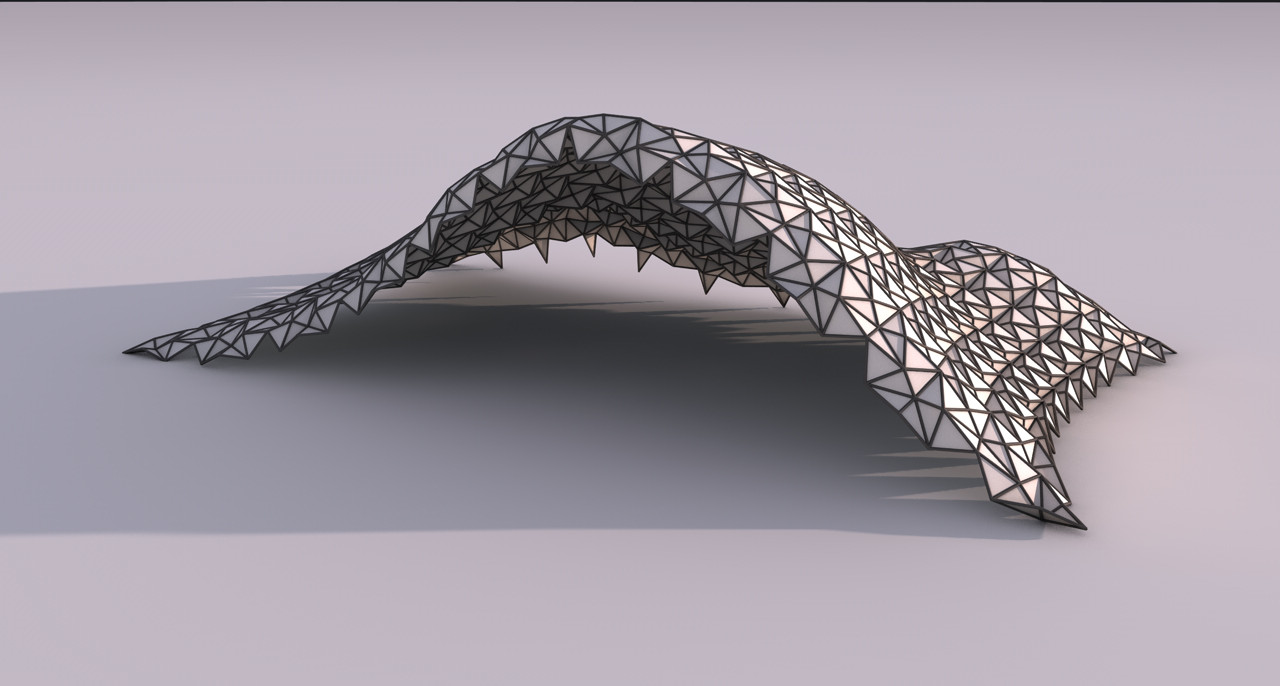

Smart materials are at the forefront of technological advancements and have the potential to revolutionize numerous sectors including automotive, aerospace, construction, healthcare, electronics, and energy. They offer benefits such as improved performance, increased durability, enhanced safety, and energy efficiency. The key types of smart materials include shape memory alloys, piezoelectric materials, electrochromic materials, thermochromic materials, and self-healing materials, among others.

The automotive industry has embraced smart materials for applications such as smart glass windows that can switch from opaque to transparent, self-repairing coatings, and shape memory alloys for active suspension systems. In aerospace, smart materials are used in aircraft components to reduce weight, enhance fuel efficiency, and improve overall performance. The construction sector utilizes smart materials for self-sensing structures, adaptive facades, and energy-efficient building systems.

In healthcare, smart materials find applications in biomedical engineering, drug delivery systems, tissue engineering, and prosthetics. They enable the development of implantable devices that respond to physiological conditions, smart fabrics for monitoring vital signs, and biodegradable materials for controlled drug release.

The electronics industry benefits from smart materials in the form of flexible displays, smart sensors, and stretchable electronics. These materials enable the production of devices with unique form factors, improved functionality, and wearable technology.

The energy sector utilizes smart materials for energy harvesting, storage, and efficiency. For instance, piezoelectric materials can convert mechanical energy into electrical energy, while thermoelectric materials enable the conversion of waste heat into usable electricity.

The global smart materials market is driven by factors such as increasing R&D investments, technological advancements, growing demand for smart consumer electronics, and the need for sustainable solutions. Additionally, the rising focus on smart cities and infrastructure development is expected to fuel the demand for smart materials in the coming years.

Key market players in the smart materials industry include Honeywell International Inc., Kyocera Corporation, Carpenter Technology Corporation, TDK Corporation, CeramTec GmbH, Noliac A/S, and LORD Corporation, among others. These companies are engaged in research, development, and commercialization of smart materials, catering to the diverse needs of different sectors.

In conclusion, the smart materials market is a dynamic and rapidly evolving industry that offers innovative solutions and advancements across multiple sectors. With their unique properties and functionalities, smart materials are poised to play a vital role in shaping the future of technology, infrastructure, and everyday life.

Comments

Post a Comment