Pipe Coatings Market: Enhancing Durability and Corrosion Resistance

The pipe coatings market refers to the industry involved in the production, distribution, and application of coatings for various types of pipes. These coatings are designed to enhance the durability, corrosion resistance, and performance of pipes used in different applications, such as oil and gas, water and wastewater, chemical processing, and infrastructure.

Pipe coatings play a crucial role in protecting pipes from corrosion, abrasion, and other forms of damage that can occur due to environmental factors, harsh substances being transported through the pipes, or external forces. By applying a protective coating to pipes, the lifespan of the pipes can be significantly extended, reducing maintenance costs and improving overall efficiency.

There are several types of pipe coatings available in the market, each with its specific properties and applications. Some common types of pipe coatings include:

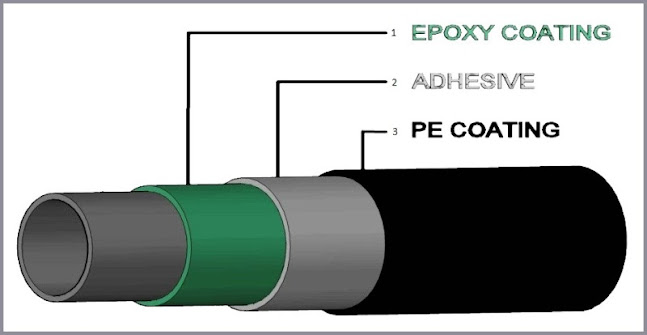

Fusion-Bonded Epoxy (FBE) Coatings: FBE coatings provide excellent corrosion resistance and are widely used in oil and gas pipelines. They are applied by heating the pipe and electrostatically applying the epoxy powder, which then fuses and forms a durable coating upon curing.

Polyethylene (PE) Coatings: PE coatings are used for both above-ground and underground pipelines. They offer good resistance to corrosion, abrasion, and impact. PE coatings can be applied through various methods such as extrusion, spraying, or wrapping.

Polyurethane (PU) Coatings: PU coatings are known for their excellent chemical resistance and mechanical properties. They are commonly used in pipelines for the transportation of chemicals, water, and wastewater. PU coatings can be applied as liquid coatings or as a foam insulation layer.

Coal Tar Enamel (CTE) Coatings: CTE coatings have been widely used in the past for corrosion protection. However, their use has decreased due to environmental concerns associated with coal tar. CTE coatings are still found in some legacy pipelines and infrastructure.

Concrete Weight Coatings (CWC): CWC is primarily used in underwater pipelines to provide weight and stability. It consists of a concrete layer applied over a corrosion protection coating, typically FBE.

The pipe coatings market is driven by various factors, including the expansion of oil and gas exploration and production activities, growing infrastructure development, increasing focus on pipeline safety and integrity, and the need for sustainable and long-lasting pipe solutions. Additionally, stringent environmental regulations and the demand for advanced coatings with improved performance characteristics are shaping the market's growth.

The market is highly competitive, with several global and regional players offering a wide range of coating solutions. Companies in the pipe coatings market often focus on research and development to develop innovative coatings with enhanced properties, such as higher corrosion resistance, improved adhesion, and better durability.

In summary, the pipe coatings market is a critical segment of the industrial coatings industry, serving to protect pipes and ensure the efficient transportation of various substances. With ongoing advancements in coating technologies and the increasing demand for durable and sustainable solutions, the pipe coatings market is expected to continue to grow in the coming years.

Comments

Post a Comment