Hydrophilic Coatings Market Global Size and Share by Top Players Forecast to 2030

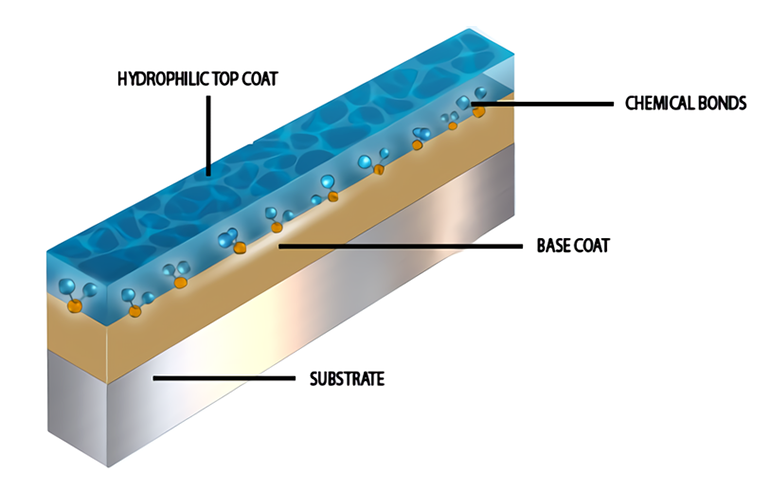

Hydrophilic coatings are thin films that have the ability to attract and hold water molecules. They are commonly used to improve the performance of medical devices and equipment, as well as to prevent water damage on various surfaces. The global hydrophilic coatings market is expected to grow significantly in the coming years, driven by increasing demand from the healthcare, automotive, and construction industries.

Market Drivers:

Increasing demand for medical devices and equipment: Hydrophilic coatings are commonly used on medical devices such as catheters, guidewires, and stents to improve their lubricity and reduce the risk of infection. The growing demand for these devices, particularly in emerging markets, is expected to drive the demand for hydrophilic coatings.

Growing awareness about water damage prevention: Hydrophilic coatings are also used to prevent water damage on various surfaces, including electronics, textiles, and building materials. With the increasing awareness about the damaging effects of water, the demand for hydrophilic coatings is expected to increase.

Rising demand for eco-friendly coatings: Hydrophilic coatings are typically made from environmentally friendly materials, such as polyethylene glycol (PEG) and polylactic acid (PLA). As consumers become more environmentally conscious, the demand for eco-friendly coatings is expected to increase.

Market Restraints:

High cost of hydrophilic coatings: Hydrophilic coatings are typically more expensive than traditional coatings, which can limit their adoption in some applications.

Limited durability: Hydrophilic coatings can lose their effectiveness over time, particularly if exposed to harsh environmental conditions. This can limit their usefulness in certain applications.

Regulatory hurdles: Hydrophilic coatings used in medical devices are subject to regulatory approval, which can be a lengthy and expensive process. This can limit the adoption of hydrophilic coatings in the medical industry.

Market Segmentation:

The global hydrophilic coatings market can be segmented based on material, substrate, application, and geography.

By Material:

- Polyurethane

- Silicone

- Acrylics

- Others

By Substrate:

- Metals

- Plastics

- Glass

- Others

By Application:

- Medical devices

- Optics

- Electronics

- Automotive

- Building materials

- Others

By Geography:

- North America

- Europe

- Asia-Pacific

- Middle East & Africa

- South America

Key Players:

- Surmodics, Inc.

- DSM Biomedical

- Hydromer Inc.

- Biocoat Inc.

- Aculon Inc.

- AdvanSource Biomaterials Corporation

- Harland Medical Systems Inc.

- Abbott Laboratories

- Royal DSM N.V.

- Covalon Technologies Ltd.

Comments

Post a Comment