Corrosion Resistant Resin Market Driving The Industry Growth, Information 2030

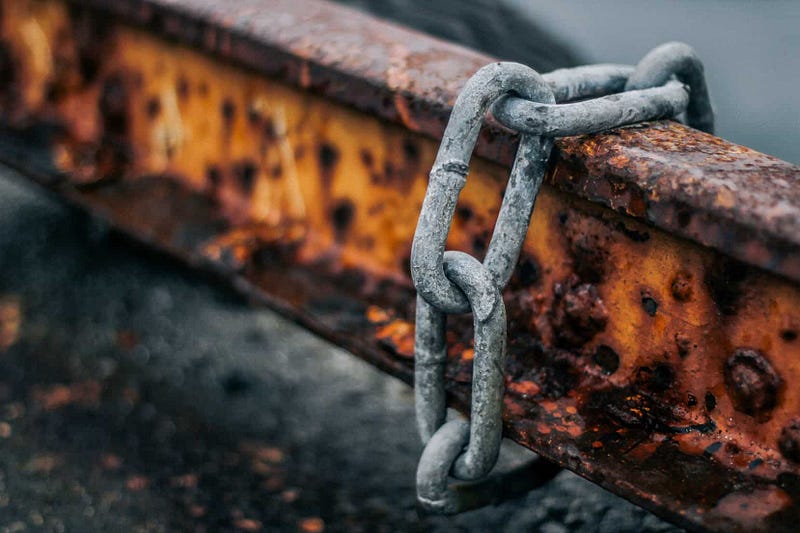

Corrosion Resistant Resin

Corrosion resistant resin refers to a type of polymer that has been specifically designed to resist the effects of corrosion, such as rust and degradation, caused by exposure to harsh chemicals, extreme temperatures, and other environmental factors. These resins are often used in a variety of industries, including construction, automotive, marine, and aerospace, where corrosion can cause significant damage and pose safety risks. Corrosion resistant resins can be made from a variety of materials, including epoxy, vinyl ester, and polyester, and are often reinforced with fibers to improve their strength and durability.

Corrosion Resistant Resin Market Overview

The corrosion resistant resin market is a growing industry, driven by increasing demand for durable and long-lasting materials in a variety of applications. The market is segmented by type, application, end-use industry, and geography. By type, the market is segmented into epoxy, vinyl ester, polyester, and others. Among these, epoxy resins are expected to dominate the market owing to their high performance and excellent corrosion resistance properties.

By application, the market is segmented into coatings, composites, and others. The coatings segment is expected to dominate the market due to the increasing demand for anti-corrosive coatings in various industries.

By end-use industry, the market is segmented into oil & gas, marine, construction, automotive, and others. The oil & gas industry is expected to be the largest segment due to the high demand for corrosion resistant materials in pipelines, storage tanks, and other equipment.

Some ofzthe key players in the market include Ashland Global Holdings, Inc., Huntsman Corporation, Hexion Inc., Reichhold LLC, Scott Bader Company Ltd., and Polynt-Reichhold Group. These companies are investing in R&D activities to develop new and advanced corrosion resistant resins to meet the growing demand from various industries.

Corrosion Resistant Resin Market Growth

The corrosion resistant resin market is expected to experience significant growth in the coming years due to various factors such as increasing demand from end-use industries, rising awareness about the benefits of corrosion-resistant materials, and growing government regulations regarding the use of such materials.

The oil & gas industry is expected to be a major contributor to the growth of the market, as it requires high-performance materials for pipelines, storage tanks, and other equipment that are exposed to harsh environments. The increasing demand for energy and the discovery of new oil and gas reserves is expected to drive the demand for corrosion resistant resins in this industry.

The construction industry is also expected to drive the growth of the market, as it requires materials that are durable and resistant to corrosion for various applications such as building facades, bridges, and tunnels. The increasing infrastructure development activities and growing construction industry in emerging economies are expected to fuel the demand for corrosion-resistant materials.

Overall, the corrosion resistant resin market is expected to grow significantly in the coming years due to the increasing demand from end-use industries and the growing awareness about the benefits of using such materials.

Corrosion Resistant Resin Market Trends

The corrosion resistant resin market is witnessing several trends that are shaping its growth trajectory. Some of the key trends are:

- Increasing demand for sustainable and eco-friendly materials: There is a growing trend towards the use of sustainable and eco-friendly materials, and this is also reflected in the corrosion resistant resin market. Manufacturers are focusing on developing resins that have a lower environmental impact, and are recyclable and biodegradable.

- Technological advancements: The use of advanced technologies such as nanotechnology and 3D printing is enabling the development of corrosion resistant resins with improved properties such as higher strength, durability, and resistance to harsh environments.

- Growing use of composites: Composites made from corrosion resistant resins and reinforcing fibers such as carbon fiber and glass fiber are increasingly being used in various applications, including aerospace, automotive, and construction. The use of composites offers several advantages such as high strength, low weight, and resistance to corrosion.

- Shift towards high-performance materials: End-use industries are increasingly demanding high-performance corrosion resistant materials that can withstand harsh environments and provide long-term protection. Manufacturers are focusing on developing resins with improved properties such as higher corrosion resistance, better adhesion, and faster curing times.

- Growing demand from emerging economies: The corrosion resistant resin market is witnessing significant growth in emerging economies such as China, India, and Brazil, driven by the increasing demand from end-use industries such as oil & gas, construction, and automotive. The rising infrastructure development activities and the growing middle-class population in these countries are expected to further drive the demand for corrosion resistant resins.

- Increasing emphasis on research and development: Manufacturers are investing in research and development activities to develop new and advanced corrosion resistant resins that meet the evolving demands of end-use industries. This is expected to drive innovation in the market and result in the development of high-performance materials that offer better protection against corrosion.

Comments

Post a Comment