Ultraviolet Uv Curable Resins Market Segment and Forecast up to 2030

Ultraviolet Uv Curable Resins

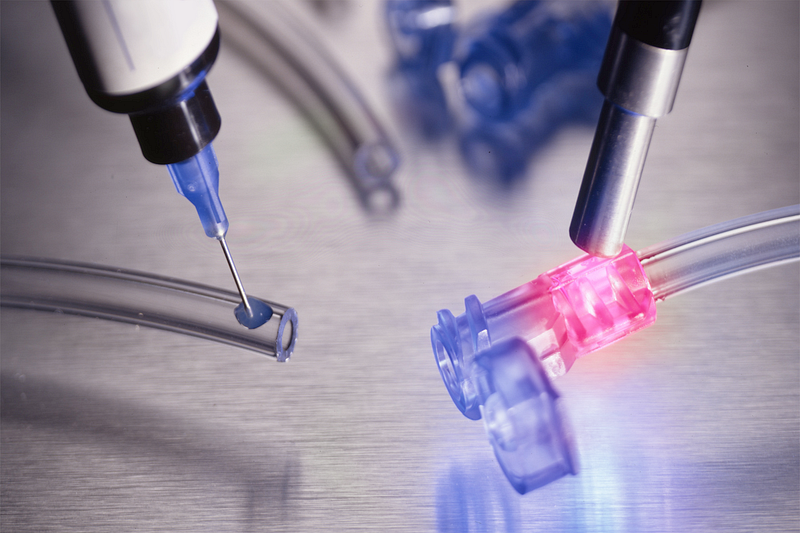

Ultraviolet (UV) curable resins are a type of resin that hardens when exposed to UV light. They are typically used in a variety of applications including coatings, adhesives, inks, and dental materials. UV curable resins are made up of oligomers, monomers, photoinitiators, and additives. Oligomers are the main building blocks of the resin, and they provide the backbone of the cured material. Monomers are smaller molecules that help to reduce the viscosity of the resin, making it easier to apply. Photoinitiators are compounds that start the curing process when exposed to UV light, and additives are used to modify the properties of the resin.

Ultraviolet Uv Curable Resins Market

The ultraviolet (UV) curable resins market has been growing steadily over the past decade and is expected to continue growing in the coming years. The market is driven by the increasing demand for sustainable and eco-friendly products, as well as the growing demand for UV curable resins in various industries, such as automotive, electronics, and printing.

The demand for UV curable resins in the coatings industry is also expected to drive market growth. UV curable coatings offer several advantages over traditional coatings, including faster curing times, improved scratch resistance, and reduced environmental impact. The automotive and aerospace industries are major consumers of UV curable coatings due to their durability and resistance to chemicals and weathering.

The electronics industry is another major consumer of UV curable resins, particularly in the production of printed circuit boards (PCBs) and other electronic components. UV curable resins offer several advantages in this industry, including faster curing times, lower processing temperatures, and reduced environmental impact. In terms of product type, oligomers are expected to be the fastest-growing segment of the UV curable resins market, due to their ability to improve the properties of the cured material, such as flexibility and adhesion.

Overall, the UV curable resins market is expected to continue growing as demand from end-use industries continues to increase, and as manufacturers develop new and innovative products to meet the needs of these industries.

Ultraviolet Uv Curable Resins Market Growth

The ultraviolet (UV) curable resins market has been experiencing steady growth in recent years and is expected to continue growing in the future. The market growth can be attributed to several factors, including the increasing demand for eco-friendly and sustainable products, the advantages of UV curable resins over traditional curing methods, and the growing demand from various end-use industries.

One of the major drivers of market growth is the increasing demand for sustainable and eco-friendly products. UV curable resins offer several advantages over traditional curing methods, including the absence of solvents and volatile organic compounds (VOCs), which makes them more environmentally friendly. As consumers become more environmentally conscious, the demand for sustainable products is expected to increase, which will drive the demand for UV curable resins.

Another factor driving market growth is the advantages of UV curable resins over traditional curing methods. UV curable resins offer faster curing times, which can increase production efficiency and reduce costs. They also offer better adhesion, chemical resistance, and durability than traditional curing methods, making them ideal for use in a variety of applications.

The growing demand from various end-use industries is also driving market growth. UV curable resins are used in a wide range of industries, including automotive, electronics, printing, and construction. As these industries continue to grow, the demand for UV curable resins is expected to increase.

In addition, advancements in technology and product innovation are expected to drive market growth. Manufacturers are continually developing new and innovative products that offer improved performance and properties, which is expected to increase demand for UV curable resins.

Ultraviolet Uv Curable Resins Market Trends

The ultraviolet (UV) curable resins market has been experiencing several trends in recent years, driven by the increasing demand for eco-friendly and sustainable products, the advantages of UV curable resins over traditional curing methods, and the growing demand from various end-use industries. Some of the major trends in the UV curable resins market are:

- Growing demand from the electronics industry: The electronics industry is one of the major consumers of UV curable resins, particularly in the production of printed circuit boards (PCBs) and other electronic components. The demand for UV curable resins in this industry is expected to continue growing due to their ability to offer faster curing times, lower processing temperatures, and improved environmental impact.

- Rising popularity of 3D printing: UV curable resins are increasingly being used in 3D printing applications, as they offer faster curing times and the ability to create complex shapes with high precision. The growing popularity of 3D printing is expected to drive demand for UV curable resins in the coming years.

- Increasing demand for coatings: The demand for UV curable coatings is expected to continue growing in various end-use industries, including automotive, aerospace, and construction. UV curable coatings offer several advantages over traditional coatings, such as faster curing times, improved scratch resistance, and reduced environmental impact.

- Advancements in product technology: Manufacturers are continually developing new and innovative products that offer improved performance and properties, such as better adhesion, chemical resistance, and durability. These advancements in product technology are expected to drive market growth by offering new and improved applications for UV curable resins.

- Growth in the Asia Pacific region: The Asia Pacific region is the fastest-growing market for UV curable resins, driven by the growing demand from end-use industries such as electronics, automotive, and construction. The region is also home to several key players in the UV curable resins market, which is expected to drive further growth in the region.

Overall, the UV curable resins market is experiencing several trends that are expected to drive growth in the coming years, including the increasing demand from various end-use industries, the advantages of UV curable resins over traditional curing methods, and advancements in product technology.

Comments

Post a Comment